EN

Outline of SAMI’s Magnesium Smelting Technology

SAMI is one of the earlier and largest companies in China engaged in engineering design and technological development (R&D) in the magnesium smelting industry. We have and hold electrolysis/reduction process and Thermal/Pidgeon process to produce metallic magnesium, as well as possess the suspension calcinations technology to produce light-burned magnesium oxide, and high-grade high-purity magnesium sand.

SAMI has created and achieved the "First" performance in China

Ø The first electrolytic magnesium production line - Fushun Aluminum Plant Magnesium Workshop;

Ø The first production line using magnesium electrolysis cells without partitions - Fushun Titanium Industry Co., Ltd.;

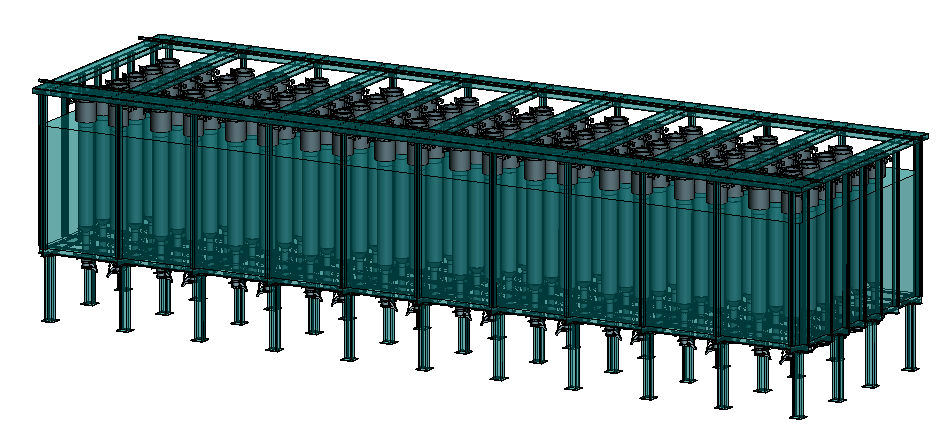

Ø The first largest 100kt/a electrolytic magnesium plant in terms of production capacity- Magnesium Plant of Qinghai Salt Lake Magnesium Industry Co., Ltd.;

Ø The first industrial scale thermal magnesium plant - Hubei Tangshan Magnesium Plant.

In 2021, in accordance with the requirements of Chalco, SAMI established the Magnesium Resource Comprehensive Utilization Research Center, not only focusing on technology research on magnesium, but also actively extending to the R&D field of comprehensive utilization of resources such as titanium and calcium, so as to positively building of excellent composite technology innovation team with professional talents working on magnesium, titanium, calcium and other smelting technology.

At present, there are over 10 engineers on magnesium R&D, more than 30 engineers on engineering industrialization, and 10-odd external-introduced experts. We have established a composite technology innovation team featured by multiple research directions, strong scientific research capabilities, precise process technology, and rich engineering experience.

Main Technologies and Indicators of SAMI:

l SAMI has Φ The 600 vertical-tank reduction furnace technology for thermal/ Pidgeon Process, achieving the following advanced indicators:

Ø Single tank production capacity reaches 120kg;

Ø Material to magnesium ratio <6.3;

Ø Energy consumption <2.5tec.

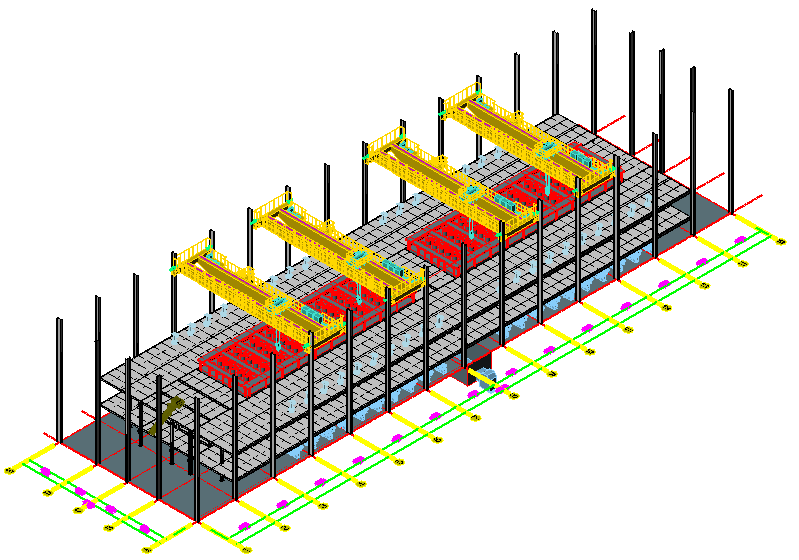

l SAMI has magnesium electrolysis/reduction technology of no-partition pot and 90-165kA multi-pole magnesium electrolysis/reduction pot, of which multi-pole magnesium electrolysis/reduction process is the world's most advanced electrolysis/reduction magnesium technology matching for sponge titanium production:

Ø A single pot production capacity of 2.8-4.4t. Mg/d;

Ø DC power consumption (in front of pot)≤ 10500 kWh/t. Mg;

Ø Chlorine concentration ≥ 95% (Wt);

Ø Liquid magnesium is not required to be refined for sponge titanium production.

l SAMI is under developing the following technologies related to magnesium smelting:

Ø Φ 1200 Large Vertical-Tank Reduction Furnace Technology for Thermal/ Pidgeon Process;

Ø Aluminum thermal method for producing magnesium metal technology;

Ø Suspension calcination technology for dolomite;

Ø Relative vacuum "One-out" clean and environmental–friendly magnesium smelting technolog

Some of Major Reference Magnesium Projects Completed and Executed by SAMI

No. | Project | Location | Capacity | Process |

1 | Midal Magnesium Project for Midal Cables Ltd. | Kingdom of Bahrain | 2*15kt/a | Pidgeon process |

2 | Metal Magnesium plant of Qinghai Salt Lake Industrial Group | Qinghai, China | 100kt/a | Electrolysis process |

3 | Solid Waste Magnesium Chloride Comprehensive Utilization Project for Anshan Hailiang Titanium Industry Co., Ltd. | Anshan, China | 36kt/a | Electrolysis process |

4 | Design and service of vertical tank reduction furnace for POSCO | South Korea | 10kt/a | Pidgeon process |

5 | Karasu Magnesium Metal Plant Project | Turkey | 15kt/a | Pidgeon process |

6 | Henan Tianrui Magnesium Plant Project | Henan, China | 80kt/a | Pidgeon process |

7 | Guangxi Guirui Magnesium Project (in two stage) | Guangxi, China | 500kt/a | Pidgeon process |

8 | Dayou Magnesium Ltd Electrolytic Magnesium Project | Hebei, China | 10kt/a | Electrolysis process |

9 | Zhenhua Titanium Ltd Electrolytic Magnesium Project | Inner Mongolia, China | 10kt/a | Electrolysis process |

Aluminium Corp all rights reserved by Beijing ICP -1 No. 05024156 Beijing public security 110401000017

Address: the people's Republic of China Beijing, Haidian District Xizhimen North Street No. 62