EN

Overview of SAMI Alumina Technology

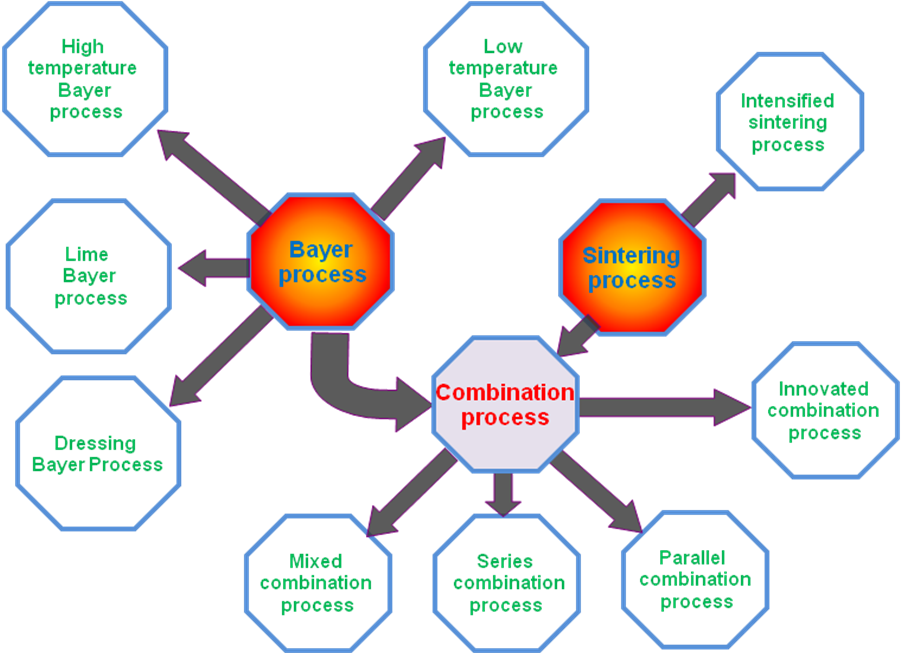

As the cradle of China's aluminum industry, SAMI has been devoting to alumina technology research, development and engineering. SAMI has profound technology accumulation, providing China alumina industry almost all the alumina production technologies in use, creating the most first times in the history of China alumina industry, such as, the first mixed combination process, series combination process, intensified sintering process, Lime Bayer process, Dressing Bayer process, Low temperature Bayer process, innovative series combination process, some unit technologies as well, such as, dual stream digestion, sweetening process, etc. with the total design capacity over 21 million tons.

SAMI is experienced in designing different process according to different bauxites sources including diaspore, boehmite, gibbsite, fly ash, etc. Low temperature Bayer process is the most focused process of SAMI at present with great technical achievement.

The Overall Technology

The Unit Technology

Raw material | • One-stage close-circuit grinding process • Fine crushing by roller press |

Digestion | • High temperature single stream digestion process • Low temperature single stream digestion process • Dual stream digestion process • Double digestion process • Sweetening process |

Residue | • High-efficiency deep-cone settler technology • Red mud filter pressing and dry stacking technology • High-efficiency filter-aid technology for control filtration |

Evaporation | • 6 or 7-effect falling film evaporation process • MVR evaporation technology |

Precipitation | • One-stage seed precipitation technology for sandy alumina production • Two-stage seed precipitation technology for sandy alumina production • Continuous carbonation precipitation technology for sandy alumina production • Organics removal technology for Bayer process • High efficiency fine hydrate recovery technology from spent liquor |

Sinter | • Low A/S clinker sintering technology • High A/S clinker intensified sintering technology • Soda-lime (limestone) sintering process • Lime firing technology of rotary or vertical kiln |

Others | • HSG/HQG high-efficiency mechanical agitation technology • Comprehensive utilization technology of exhaust steam in the whole plant • Exhaust gas waste heat recovery technology of calcination flue gas |

Main Performance Indicator

With the development of modern technology and equipment, SAMI successfully upgraded its low temperature Bayer process with the following parameters.

Single line production capacity | 100~2,000kt/a |

Fresh water consumption | ~0t/t- Al2O3 |

Comprehensive energy consumption | 3 |

Floor area consumption | ≤7GJ/ t-Al2O3 |

Design and R&D Platform

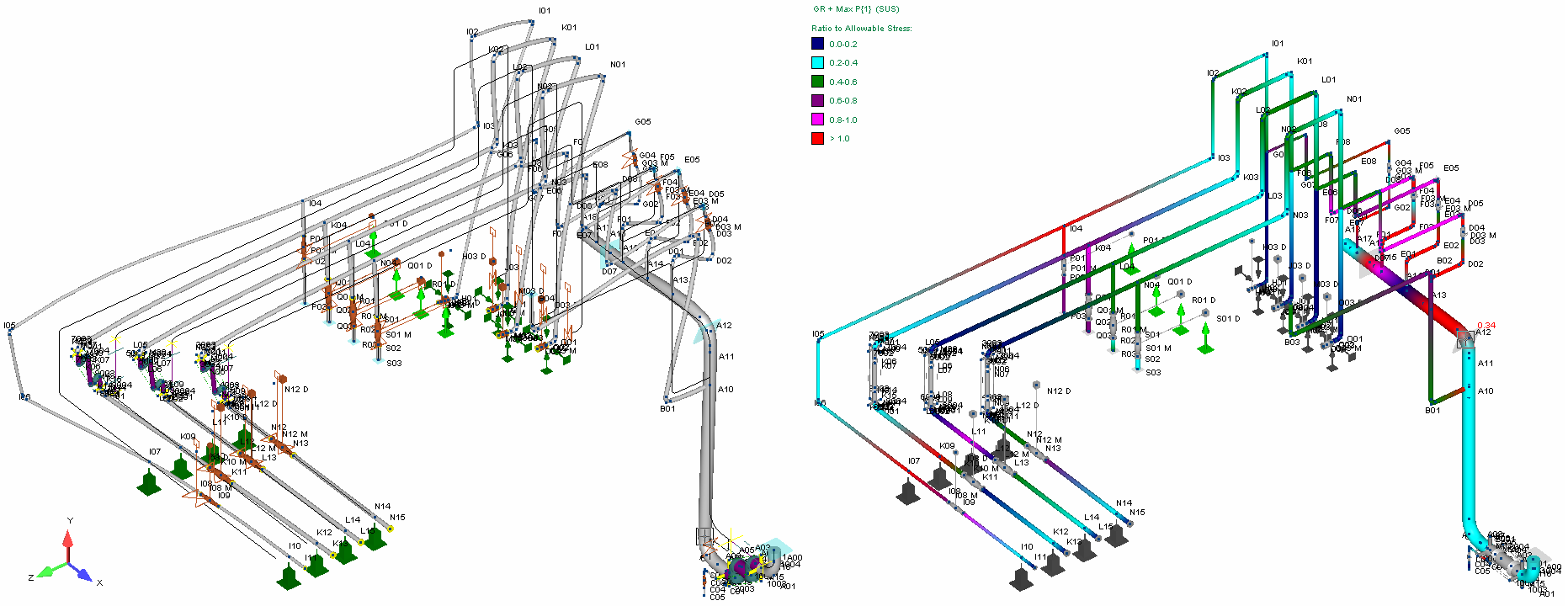

Our tool platform keeps pace with the times and keeps pace with the international advanced level. We use Syscad to simulate the process, with Bently, Solidworks and PDsoft to complete the engineering design, as well as using Auopipe to analysis the pipe stress, and using Ansys to simulate the fluid.

|

|

|

Bauxite Grinding Plant Model | Bayer Unit Simulation | Settler Model |

Stress Analysis

Aluminium Corp all rights reserved by Beijing ICP -1 No. 05024156 Beijing public security 110401000017

Address: the people's Republic of China Beijing, Haidian District Xizhimen North Street No. 62